Experienced Turnaround Planning Management

At Zyme-Flow® Decon Technology, we contribute much of our success and zero recordable injuries to excellent turnaround planning management. Highly experienced decontamination planners work with refinery personnel to ensure tasks are managed and consistent with customer design limits and specifications while staying on schedule.

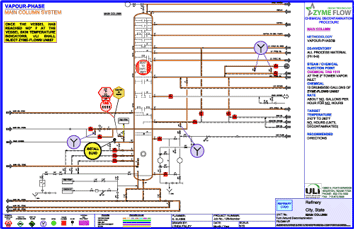

To aid in the safe execution of the shutdown, customized decontamination procedures, drawings, and timelines are provided to ensure the decontamination portion of the shutdown is carried out as smoothly and efficiently as possible. Our on-staff CAD technicians work closely with our decontamination planners to provide user-friendly conveyances of each plant’s P&ID’s. The easy to read CAD illustrations are powerful tools that integrate into our Zyme-Flow procedures to ensure your operations personnel can easily track and understand the decontamination status.

Turnaround Planning Process

Comprehensive interface with planners, operations, process engineering and supervisors

On-site walk down of equipment and piping

Integration of decontamination procedures into normal plant procedures

Accurate calculation of waste volumes for disposal

Pre-job identification of chemical injection points fully documented